Water Based Mud Systems

As operators drill deeper horizontally through the formation, pressure loss through the drill bit and drill pipe increases, the pump pressure must increase to maintain consistent flow. As this occurs, equivalent circulating density (ECD) increase and applies additional pressure on the formation. To keep ECD down, pressure management must be optimized to minimize the risk of lost circulation. To do this requires optimal hole cleaning while keeping ECD at a minimum. Complicating matters, many of the polymers/additives in standard HPWBM (high performance water base mud system) formulations cannot resist typical oilfield contaminants such as calcium influxes, magnesium influxes, hyalites and carbonates. As a result, expensive and complicated treatments are required.

High performance water-based mud systems are intended to reduce formation damage while providing improved pressure management and significant cost savings.

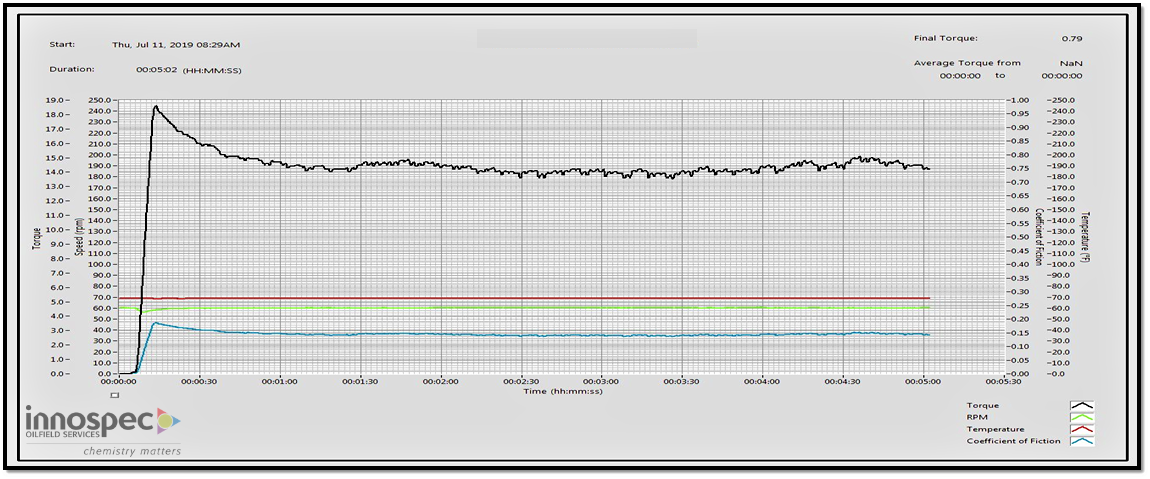

MaxWell™

Offering major cost and performance advantages over both oil-based and standard HPWBM systems, MaxWell™ resists oilfield contaminants and is superior to oil-based systems in safety and environmental impact. Additional MaxWell advantages that include:

- Outstanding coefficient of friction

- Reduced rig time

- Highly resistant to contaminates

- Builds its own solids-free, easy clean up filtercake

with the MaxWell system it much lower at .14

this is below the average COF of OBM which is .05 – .09

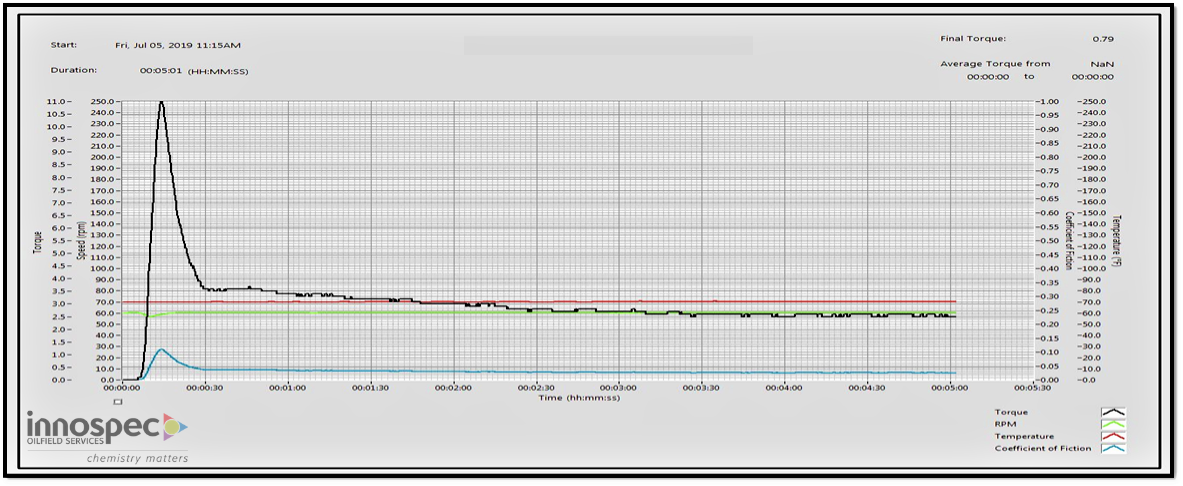

Redi-Guard™

Innospec’s Redi-Guard mud system offers significant advantages over other standard HPWBM systems. This environmentally friendly, biodegradable product develops a more robust system, which results in less non-productive time. In addition to being more efficient and safe for the environment, it also:

- Optimizes hole cleaning efficiency with faster ROPs

- Lower ECDS/ significantly reduced risk of down hole losses

- Significantly improves clay and shale encapsulation

- Significantly improves less formation damage with better logs