Understanding the difference between GDi and PFI engines.

Innospec explains why this matters. GDi engines have taken fuel injection technology to the next level.

Gasoline combustion engines have come a long way since Luigi De Cristoforis first invented the carburettor in 1876. However, mixing fuel with air in the carburettor before it entered the combustion chamber was still the main technology being used in gasoline vehicles right through to the 1980s.

It was only in this decade that Original Equipment Manufacturers (OEMs) started the transition from carburettor engines to single point fuel injection to overcome some driveability issues and increasing concern over exhaust emissions. The technology was moving quickly though.

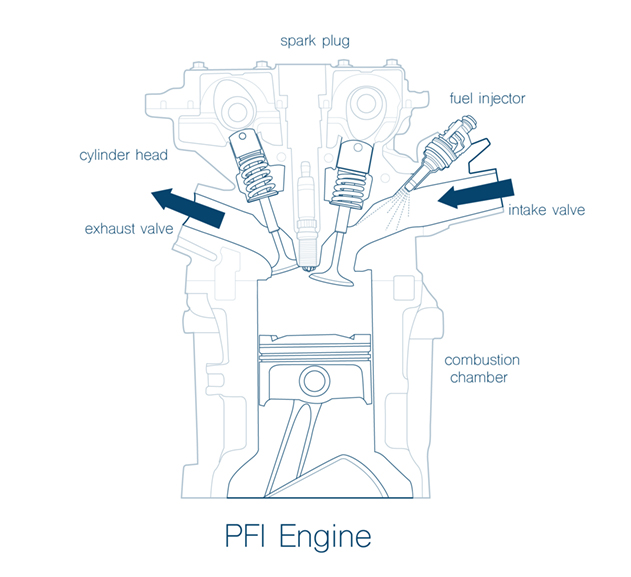

When PFI emerged at the end of the 1980s, it was a major leap forward in fuel injection design. It overcame many of the performance issues connected with single point injection and the earlier carburettor engines. In Port Fuel Injection (PFI) or Multi Port Fuel Injection (MPFI) fuel is injected into the intake port of each combustion chamber via a dedicated injector.

PFI engines use a three-way catalytic converter, exhaust sensors and computer-controlled engine management to constantly adjust the fuel-to-air ratio injected into each cylinder. However, technology evolves and compared to the current Gasoline Direct Injection (GDi) engine technology, PFI is not as fuel efficient or capable of meeting today’s ever more stringent emission standards.

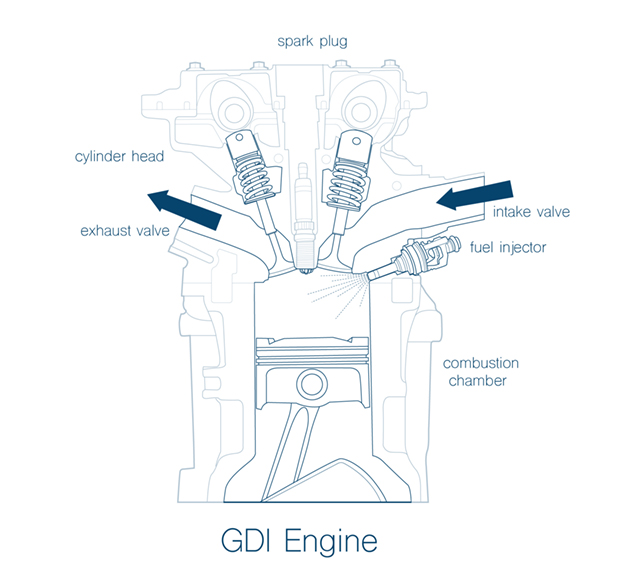

With a GDi engine, fuel is injected directly into the combustion chamber, not the intake port. The benefit of this system is that fuel is used more efficiently. Without the need to pump fuel into the intake port, mechanical and pumping losses are reduced significantly.

In a GDi engine fuel is also injected at higher pressures so fuel droplet sizes are smaller. Injection pressures are in excess of 100 bar compared to a PFI injection pressure of 3 to 5 bar. Fuel droplet size with GDi are <20μm compared to a PFI droplet size of 120 to 200μm.

As a result, GDi engines deliver a higher power output for the same amount of fuel. Onboard management systems keep the whole process in balance and accurately control regulated emissions. The engine management system fires the injectors at the optimum moment for a specific duration based on the demand and driving conditions at that moment. At the same time the vehicle computer calculates if the engine is running too rich (too much fuel) or too lean (too little fuel) and immediately adjusts the injector pulse width (IPW) accordingly.

The latest generation of GDi engines are sophisticated machines that operate to very tight tolerances. To deliver improved fuel economy and lower emissions, GDi technology uses precision components in a high-pressure environment. Keeping the injector system clean is critical to engine performance.

Fuel additive chemistry is built on an understanding of how these different engines work. For many years Innospec has adapted and developed its fuel additive packages to meet the demands of the latest engine technology. Understanding the engineering that underpins different engine designs is key to this process.