Friction Reducers

As a key component in slickwater applications, traditional emulsion-based friction reducers have long been a mainstay of the North American completions market.

Friction reducers are intended to reduce the friction in the wellbore during the drilling and stimulation processes in unconventional reservoirs such as coal beds and shales. The large volumes of water pumped, and high rates required, result in high friction pressures from turbulent fluid flow. Cationic or anionic friction reducers reduce turbulence and minimize friction losses.

However, these polyacrylamide-based liquid invert emulsions (friction reducers) are limited by poor water quality tolerance, limited proppant carrying capacity, and escalating costs. Until now.

HiRate™ High Efficiency Friction Reducers (HEFRs)

Innospec Oilfield Services (IOS) offers a wide range of proprietary formula liquid or dry friction reducers specifically designed for the unconventional challenges that face many clients today: to deliver lower pumping pressures using less product in less time.

Proven superior performance in slickwater fracturing.

Since 2015, IOS has focused on emulsion chemistry, with a goal of having its application deliver far more than mere reduced friction. Today, Innospec’s extensive portfolio of High Efficiency Friction Reducers (HEFR), such as our HiRate Plus and HiRate MAXX series, successfully meet a myriad of customer needs with industry-leading features and benefits, including:

- Less product per stage

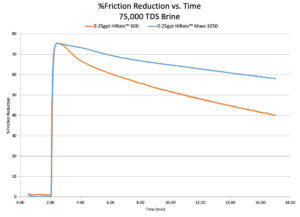

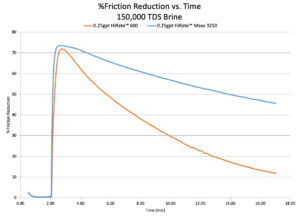

- Superior friction reduction

- Ultra-fast inversion

- Significant cost savings

- Brine tolerant formulations

- Operational simplicity

- Reduced and stabilized treating pressures throughout formation

- Smaller onsite footprint

- Better sand transport

- Aggressive sand ramps

- Enhanced safety